KEMP Tools - Wireless Torque Transducer & Controller

KEMP Wireless Torque Transducer & Controller

KEMP Tools - Wireless Torque Transducer & Controller

Torque Wrench , Air Tool ,Cordless Tool with Wireless Torque Transducer.

Fastening torque data can be transfer and saved - KEMP Tools

Wireless Torque Transducer

Controller

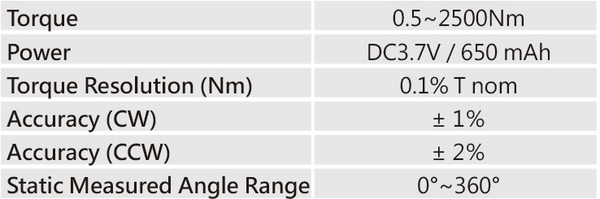

Wireless Torque Transducer

■ Standard : 1.Transducer 2.Motor Cable 3.Switch magnetic

■ Option: Dongle

Features

■ Versatile operation modes for option: 1.Oil pulse tool 2.Impact wrench

3.Clutch wrench 4.Torque wrench 5.Electric Screwdriver 6.Click Torque Wrench

■ Signal according to 1.Torque 2.Angle

■ RF Frequency band: 60 frequency band used with the E-BTM-C Torque Controller.

■ Torque Transducer self-monitoring (electric+transmitting+torque+angle+usage count)

■ On & off Reed switch (magnetic on/off) / Off when non transmitting torque 5min up.

■ LED signal light [ Two-tone Blue/Orange: Blue Light on: RF ok / Blue- flicker:system

initialize / Orange- flicker:Error ]

[ Two-tone Red/Green: Red Light on:charging / Green Light on:charge complete ]

■ The over-limit vibration level: the operation cycles, and the over-torque information

will be recorded for the ease of warranty judgment.

■ KEMP APP for smart phone or pad,APP on Android system only.

■ Warranty One year with use correctly and under maximum torque limit specified,

Within dynamic 200,000 cycles or static 500,000 cycles.

(Built-in record for usage time and count)

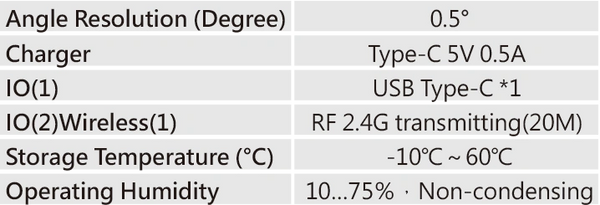

Wireless Torque Controller

KEMP Tools

■ Standard : 1.Controller 2.Motor Cable 3.Antennax2 4.Filter Regulator+Lubricator 5.Air inlet coupler

■ Option: 1.Tri-color warning light 2.Barcode scaner 3.PrinterFeatures

Features

■ Versatile tools support:

Dynamic Tightening: Oil pulse Tools, Shut-off type Clutch, Torque multiplier, Click Torque Wrench

Static Tightening: Torque wrench, Click Torque Wrench, Torque multiplier

■ Multiple control methods: Dynamic Tightening: 1.Torque 2.Track

Static Tightening: 1.Torque 2.Click Torque Monitor 3.Click Torque Track 4.Monitor

■ Signal 1.Wireless transducer 2.Air pressure mode

■ Torque adjustment 1.Deviation value corrected 2.Override value corrected

■ Torque range verify: Easy set-up in minutes

■ Torque Control Methods Set up torque control range

■ Automatic air consumption rate measurement and selection for the broadest torque

control range

■ Built-in preset parameters and job sequences up for the ease of assembly works

(Suggest Air inlet 90~110psi)

■ Built-in torque fastening stage & bolting sequence control.

■ Number of bolts: Preset the number of bolts to be fastened. Only when all bolts of each

stage fastened, the system will switch to next stage and regulate the air pressure and

flow rate correspondingly >and automatically

■ Torque Compensation: The system will compensate the torque loss that may caused by

the variation in the bolted joint hardness or the rise in temperature of hydraulic fluid of

pulse wrench or the posture of operator to hold the tools during the process

automatically within its allowable working air pressure range.

■ Monitoring: Functions with VNC remote configuration or monitoring with PC, smart

phone or tablet through Mobile APP are optional upon request

■ Supervisor operator: Functions are restricted by privilege rating. Also record log in code

and using time.

■ Dynamic torque controllable accuracy:± 5% ~ ±15%

■ Tool database: 10 set parameter for each tool category

■ Productive database: 10 set parameter for productive

■ Operation records traceable through USB, Ethernet or exported to the cloud server

through wired or wireless connections.

Aluminum alloy body min. air pressure 80psi to max. air pressure 110psi .

Included accessories:

2 x Antenna • 1 x Motor Cable • 1 x FRL(Filter Regulator+Lubricator) • 1 x 1/2"air-intake pipe • 1 x 1/2"Air inlet coupler

※ Note: Recommended min. air pressure of the torque controller is 80psi=0.54bar, which should not be lower than the pressure to avoid affect product functions and abnormalities.